Sté ELITEC

customer since 2006

Without training, without any knowledge of CN ,...

and after only a few hours of use, ...

Mr Peireira from ELITEC programs a 2.5-axis mill!

(26/09/2007)

La Société Elitec …

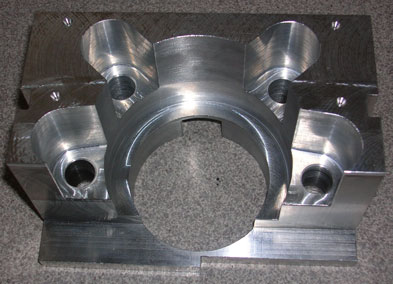

Created in 1993 ELITEC now has 5 staff. The production floor has 2 CNC Mills and 3 CNC lathes. ELITEC is involved in various industries such as, medical, special machines, jigs and mechatronics.

|

|

No CAM experience

Before the purchase of Easymill, ELITEC engineers produced their programs manually at the machines. Mr Peireira (MD) has no experience of CAD / CAM and the NC programmers, have only their education to rely on. Mr Peireira quickly identified issues with this manual process:

1 - Background programming (while the machine is working) is possible but not done as it is difficult to concentrate near an operating machine.

2 – No computer connection, so saving and modifying programs is difficult.

3 - The programming of complex shapes is always outsourced so lacks flexibility.

4 - Programming is long and tedious. Tests are numerous and time consuming.

In response to this Mr Peireira, began looking for a 2.5D CAM that was "Simple, quick to implement and not expensive. Initially a second keypad able to handle more complex shapes was investigated.

Mr Peireira wanted a quick and safe choice. For his current requirements, he discovered Easymill on the internet. He tried the software free. It meets his needs and has no financial risk. For 3D parts, a high end CAD / CAM package is chosen that is compatible with Easymill.

Setting up

Mr Peireira himself was the first to use Easymill. He had used Easymill when making his choice of CAM packages but had no further ”training”. His first program takes 1.5 hours (drawing, tool path definition and post-processing).

For an untrained person, first discovering CAM and one who barely knows the procedure for homing his machines, and in addition has no programming experience this is an outstanding achievement!!

As for the engineers, however, there are some acceptance issues. "I work faster entering code by hand" he was told. Mr Peireira took up the challenge and programs the following for them: a design with 6 holes, a spiral cut pocket, and a finishing pass.

The programming time on Easymill: 5 minutes - and the program is 200 lines long (Heidenhain). The engineers agree that they are unable to enter the 200 lines in 5 minutes!

With hindsight he declared:

"I found the software very pleasant to use, I don’t think we can continue with manual programming. The key advantages are many: Value, Price, ease of implementation, there are no surprises in setting up the package as everything is included, it is an effective CAM software system for 2D and 2.5D

With Easymill there is no more testing, it is a highly suitable tool for a shop like mine. In addition the service is marvellous, at no time have I been stonewalled.

I would say that today, we have increased machine usage by 20 to 30%, and we have also become more flexible since there are now more people who can program my machines.

A final example to conclude: we had a series of 10 pieces that took 7 hours machining with a program "by hand" but only took 5 hours with Easymill. Of course, now that programs are done more quickly, we can afford the time to optimize them. “I'm very pleased! " "

|

|

|